Did you ever wonder how, exactly, the little parts that run in your computer or smartphone are made? It’s pretty fascinating! All of this is done thanks to the pick and place machines. These wonderful devices are used to accurately and quickly plant parts onto boards, so they play a big role in the world of electronics.

We find the method a pick and place machine operates in to be intriguing. The solution those researchers developed is something the company now calls NeuraRobot, a robotic arm that can move like a human hand. The thousands of tiny pieces are then picked up by this robotic arm and placed onto a circuit board. Repeat until all the pieces are in their places. Its probably similar to assembling a ton of Lego pieces into an art if you did a puzzle.

Pick and place machines can drastically increase the speed of electronics production. They operate very rapidly, and do not get wrong as proper. However, some of these machines can place hundreds of parts on a circuit board in just a few minutes! That is something which would have taken hours to do by hand!

In addition to the increase in speed makes these machines efficient and keep things looking good. With the capacity to work for long periods without breaks they help in uninterrupted production process. This way, more products can be produced in less time which is perfect for manufacturing enterprises that are looking to cater the demands of their customers.

How do Pick and Place Machines Transform the Way Things are Manufactured in Factories? And a very precise position control that makes possible the increase of quality in production. Thanks to these machines, factories have been able to produce complex circuit boards and tiny electronics components that would be very difficult (if not impossible) for a human being todo by hand. It means new techniques and advances in technology can be discovered, unlocked by this precision.

One of the greatest things about using pick and place machines is that it can greatly reduce errors. Humans deliberately and carefully put parts in place, but even the steadiest hands can make mistakes;predesigned apparatus on a machine is designed to ensure there are no, or as few human errors possible. It's like a never-having-to-sleep, always-right BFF!

They have sensors that alarm them when a part is at the wrong place. A machine can immediately correct that if a part is wronly placed. It ensures everything is correct and that also means less waste of course, which are key ingredients for creating high-quality results. Companies are now able to produce higher quality products and at the same time save materials.

Professional designers offer the best quality solutions meet client needs. High-tech equipment readily available support spoiler design. 3D printing CNC processing material testing product simulations, the latest technology solid base the development automated pick and place machine.

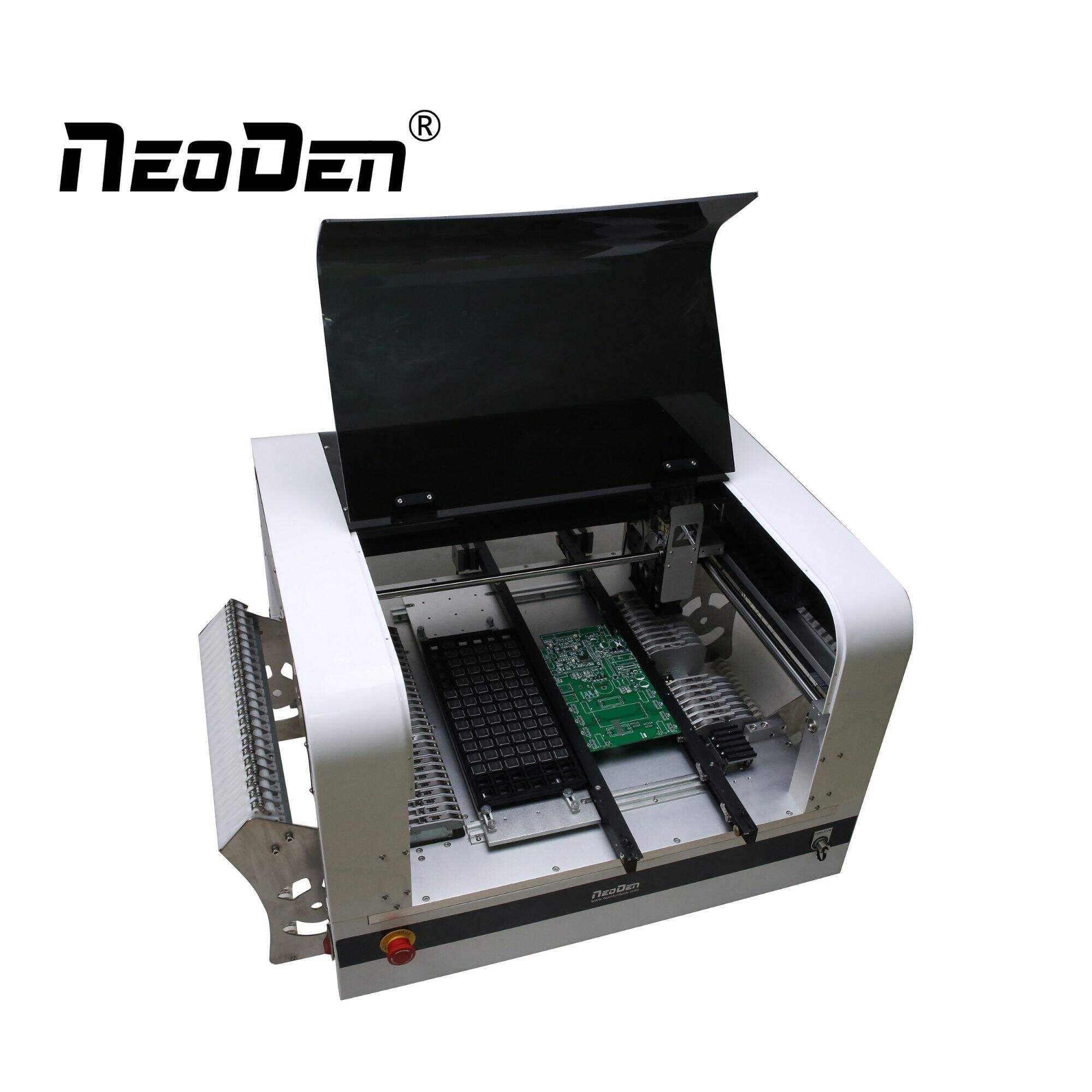

Zhejiang NeoDen Technology Co., Ltd. been automated pick and place machine exporting various small pick place machines 2010. NeoDen built strong reputation world-wide customers thanks our vast experience R&D well-trained production. We confident we'll develop items meet needs customers marketplace.

NeoDen PNP machines ideal R&D professional prototyping, addition small - medium-sized batch production. They excellent performance precision. NeoDen continued design new products, improve technology research over past 10 years.

We believe success can't automated pick and place machine without strong partnerships we actively seeking cooperation. We cooperate business partners global Ecosystem provide more efficient sales support superior technical support.

Copyright © Zhejiang NeoDen Technology Co., Ltd. All Rights Reserved - Privacy Policy