Whether you own a business, are looking into starting one or even enjoy assembling your lighting applications on new LED boards as a DIY project, the truth is that having an efficient pick and place machine in your equipment can really make all the difference.

Do you wish that there was a better way to put LED components on circuit boards than by hand? Enter the LED SMT pick and place machine! This process is more of an automated one from the point on, that streamlines your business to become faster and more efficient.

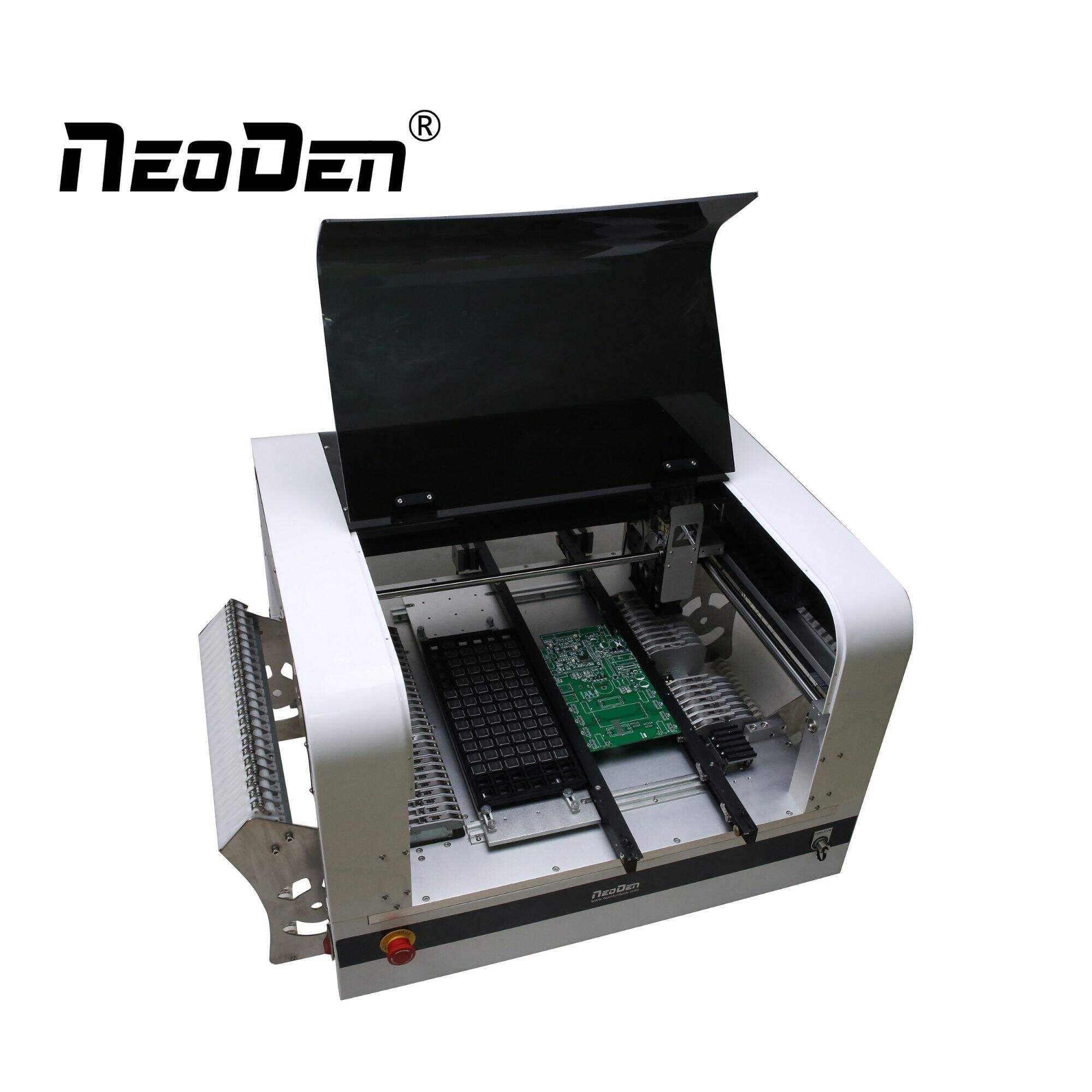

LED SMT Pick and Place Machine Features

This machine not only saves time but also money reducing errors that can occur by hand. You can fix a lot of parts at once and that allows you to produce more products in lesser time. Also, it means you will have less errors and thus not wasting materials.

Technology and Safety

The LED SMT pick and places machine is one of the most advanced in circuit board production. Smart cameras put the right parts inside repetitively with each use Safety tools (stop button, light barriers), for user protection

This machine is used in industries to place LED parts on PCBs. LED lights, TV screens and other electronic displays require it. Just power it, load your code, put the board in align to camera and click start.

This unit is sturdy and uses quality parts making it long lasting and above all very effective. It is designed to be performant, minimize errors and satisfy customer demand. Industries where it is used include cars, electronics, planes and lights

Like any machine, it requires maintenance to function properly. The manufacturer uses an operator to refurbish customers, adjust their products and repair warranties if anything breaks.

So here is the magic hammer, LED SMT Pick and Place Machine.

Do you think manually placing LED components on printed circuit boards (PCBs) is a burden? Say good riddance to these extra problems by switching over to the LED SMT pick and place machine, a new generation of high-tech manufacturers that refines your manufacturing process which increase business output.

Benefits of LED SMT Pick and Place Machine

The LED SMT pick and place machine provides multiple advantages, like higher time efficiency, savings in costs as well as high-precision. It is capable of attaching thousands of components in a few seconds which makes it shoot up your production rate and save time over traditional manual pcb assembly methods. It also promises to lower the costs of manufacturing, as there would be lesser builts-in errors compared to manual assembly. Its accuracy ensures that everything is placed perfectly on the board without waste and with complete utilization of material.

The LED SMT pick and place machine is currently regarded as the leading technology in the world of picking and placing capable equipment due to its unique, highly developed design for PCB production. This machine is equipped with complex software and cameras that are good at recognizing and placing all the components in correct order on board again.

We led smt pick and place machine success cannot achieved without strong partnership we actively seeking cooperation. We cooperate partners global Ecosystem offer higher-quality sales technical assistance.

excellent performance, high accuracy dependability led smt pick and place machine PNP machines make ideal R&D, professional prototyping small medium batch production. Over last ten years, we continued advance technology, research development innovative products.

Professional designers provide top quality led smt pick and place machine meet customer requirements. Modern equipment available support spoiler design. 3D printing CNC processing testing materials product simulations, the most recent technology provides strong foundation spoiler development.

Zhejiang NeoDen Technology Co., Ltd. been producing led smt pick and place machine small machines picking placing 2010. Taking advantage our own vast experience R&D well-trained production, NeoDen wins great reputation customers around world. We confident we produce items meet needs market our customers.

Copyright © Zhejiang NeoDen Technology Co., Ltd. All Rights Reserved - Privacy Policy