Nowadays, electronic manufacturing fast development around surface mount technology (SMT) in the world. We have no choice but to improve the efficiency of our SMT machine if we want better competitive ability. One of the ways to do this is with advanced programming concepts.

The critical step is to optimize the pick and place program. This mechanism based on size & shape wise, as well as multiple tier feeder system with picker should be able to do proper matching of picked complementary component at a time in this process. This help reduce idle phase and intensity the manufacturing productivity.

In addition, a lean manufacturing approach can also enhance efficiency. It is a tactic focused on minimizing waste, but the way it does this by using only what you need and scheduling your SMT machine movements. Using a ' just in time' delivery system means parts are delivered on-demand rather than waiting to be stored.

Cons: SMT machines will continue to face manufacturing yield problems, despite the use of state-of-the-art electronics. However, with the right methods and tools they can be reduced.

Component misplacement: This happens due to the incorrect feeder positioning or pick-and-place location errors. The solution involves the rigorous SMT machine maintenance and sensitivity of calibration. The addition of a vision system also prevents production halts by enabling on-the-fly error detection.

This is a common error, associated with stencil design problem or nozzle wear causing the solderpaste misalignment. The potential for errors can be reduced by regularly inspecting and replacing nozzles, using a good solder pasteand well optimized stencil designs.

Select SMT machine properly for high Production advantages 1. This included many such as production volume, component complexity and the highest budget allowed.

Tabletop versions are ideal for small throughputs Smaller machines themselves are cheaper to purchase and operate Overall this makes them more than perfect for anyone who is still in their startup phase or even as commercial equipment such businesses use. On the other hand high volume production will demand a multi-head SMT machine with ultra fast placement speeds that take care of various component sizes and shapes.

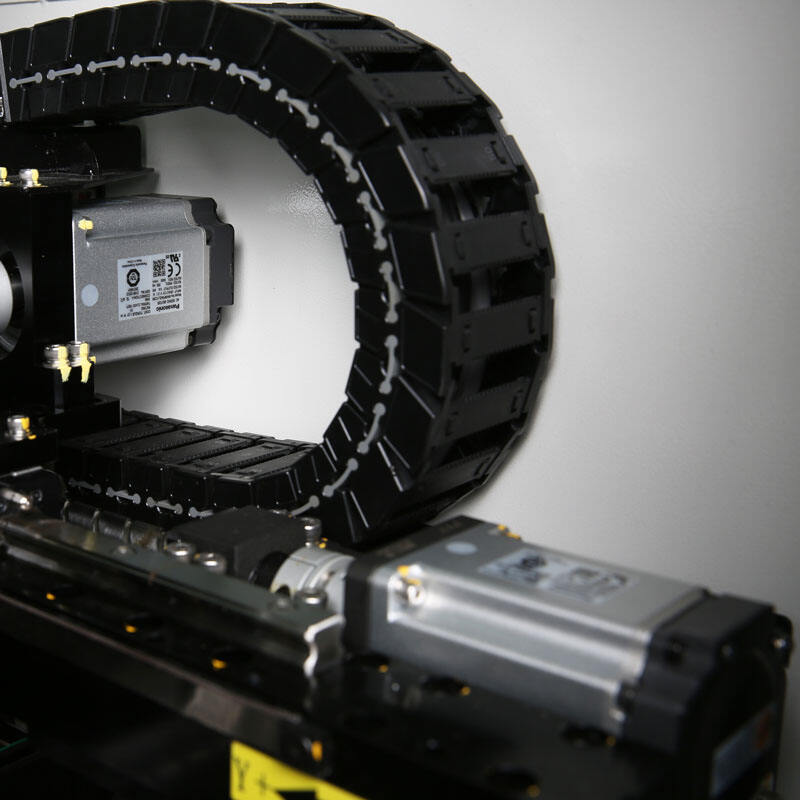

Today, high-tech SMT machines form the basis for electronics manufacturing and they not only increase efficiency but also productivity and flexibility. By using these advanced features like vision systems, multiple heads and high-end feeders technologies for ultra-fast placement components with very high accuracies.

The modern SMT machines are highly advantageous because of the capability to handle a broad range of types and shapes in component sizes, suitable for several applications upstream. Their sophisticated monitoring and adjustment software also provide immediate sight of the assembly line process for unparalleled production efficiency.

There are many innovations and trends in SMT machines, this will break the boundaries of electronic manufacturing as technology advances.

The key trend is a shift towards AI and machine learning systems now being integrated in SMT machines. After all, it employs similar plant data for machine learning to take place in order to allow machines can learn from biases and correct them with at higher error rates but more reliable output.

In electronic manufacturing, Industry 4.0 principle like smart factory with line technologies of production-floor (like Internet of Things and cloud computing) are also trending to integration together as a part. It enables live plant monitoring and allows you to predict equipment failure before it happens.

Traditional SMT machines have been endowed with robotic and automatic manufacturing technologies as well for years also. One of the biggest things you might have heard about in that vein - though it's talked up breathlessly whenever electronic manufacturing is discussed - are collaborative robots (or "cobots" as they're often called) and how these machines can be placed next to human operators on assembly lines, doing all manner of repetitive tasks where precision really counts.

To manufacture electronics successfully, the thing of most importance is to increase more efficiency in production from your own SMT machines. Using more advanced programming methods will help manufacturers avoid the common mistakes and select the right machine that is best suited for their production processes. We are witnessing new state-of-the-art machines in assembly lines and AI, IoT (Industry 4.0) seems like a mere tip of an iceberg where more change-oriented trends can be witnessed to reshape the complete scenario of SMT Assembly manufacturing at scale.

2010 Zhejiang NeoDen Technology Co., Ltd. produces exports variety small pick-andplace devices. NeoDen established solid image international customers using our years knowledge R&D well-trained production. We believe we produce items meet needs smt machine customers.

We actively look partners we believe impossible succeed without. We collaborate partners global Ecosystem provide more efficient smt machine support superior technical support.

Professional designers provide top quality smt machine meet customer requirements. Modern equipment available support spoiler design. 3D printing CNC processing testing materials product simulations, the most recent technology provides strong foundation spoiler development.

excellent performance, high precision dependability NeoDen PNP smt machine make perfect R&D, professional prototyping small medium batch production. past ten years, we continued enhance technology, research development new products.

Copyright © Zhejiang NeoDen Technology Co., Ltd. All Rights Reserved - Privacy Policy