Pick and Place Equipment: Simplifying Manufacturing Challenges

Are you fed up with struggling and different manufacturing? Don't worry! Pick and place equipment will revolutionize the genuine ways you manage your manufacturing requirements. These machines are made to help you save time, work, and NeoDen Technology resources, although ensuring a functional safer environment. Keep reading to find out more concerning the advantages, innovation, safety, use, service, quality, and application with this groundbreaking equipment.

Advantages of Pick and Place Equipment

Pick and place equipment is developed to boost their manufacturing effectiveness by automating the entire means of picking up and placing items in an specific area. This automation technologies helps increase productivity, up speed the process, and reduces the trouble associated and work. You could now automate repeated work, making their workforce to spotlight additional very duties important. Furthermore, utilizing pick and place equipment assists to scale back error prices, which means greater quality end products.

Innovation in Pick and Place Equipment

The place and pick equipment marketplace has constantly innovation encountered the growth of revolutionary production strategies and technologies. With all the increasing demand high-efficiency and performance in commercial applications, manufacturers allow us picking and placing machines being versatile, agile, and an easy task to use. The development of smart and intelligent machines the industry, with automated robots providing greater accuracy, rate, and agility. These cutting-edge machines is designed with sensors, digital cameras, and eyesight systems, letting them identify objects, make alterations, and perform make use of precision.

Safety with Pick and Place Equipment

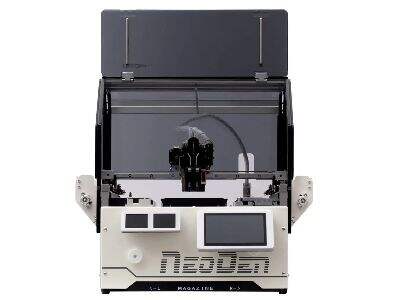

Safety is paramount in manufacturing, and pick and place equipment has gone to great lengths to make NeoDen4 sure a work safer place. The need for manual work is eliminated, ensuring their workforce remains safe from hazardous production surroundings with the automated procedure. Additionally, some picking and placing machines designed with sensors and alarms that may identify any abnormalities, preventing accidents from happening. With your precautions, your is guaranteed a top amount of staff safety, eventually minimizing employee downtime.

How to Use Pick and Place Equipment

Pick and place equipment is an easy task to operate, when installed. The machines are user-friendly, and most providers equipping all of them with easy-to-use control panels and interfaces, enabling individuals to work them minus complications. Besides, manufacturers usually create product manuals, videos, and other materials which can be instructional directing your on how to use and uphold the equipment. That you do not would you like to own any formal education or experience with using the machines it is possible to regulate the settings according to your needs as they come pre-programmed and.

Quality of Pick and Place Equipment

Pick and place equipment is created for efficiency and durability. They include top-quality robust materials, reliable, and efficient, which ensures maintenance and low longevity. The machines go through comprehensive testing to make certain it works to your maker's specs, guaranteeing high efficiency and quality. The seek out quality is essential in this industry, and manufacturers constantly enhance the NeoDen10 quality associated with the equipment to confirm they meet with the changing specifications of this users.

Application of Pick and Place Equipment

Pick and place equipment has often applications numerous different industries as for example automotive, electronics, medical, items, beverage, and packaging companies. In automotive manufacturing, picking and placing machines to set up tiny components connect various areas of the motor. Into the electronics industry, picking and placing machines to manufacture electronic circuit. Meanwhile, into the medical industry picking and placing machines help pick up surgical instruments and place them in sterilization chambers. The NeoDen IN12 machines' flexibility permits businesses to use them for various applications, making them the valuable asset any manufacturing line.