If you consider how many of the things that you like the most, for example, tablets, smartphones, and game consoles, are produced, you would be amazed to learn that they all originate from a single piece known as a printed circuit board, or PCB. The PCBs are particularly valuable because they act as 'brains' of electronic gadgets. They connect all the different pieces together so that the devices work the way they should. No PCBs, you can't even use your gadgets!

How SMT Machines Operate

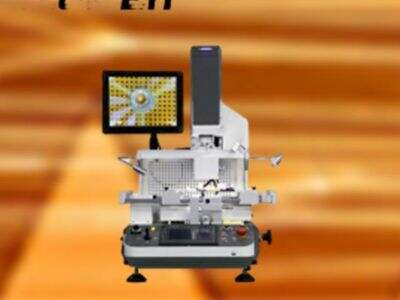

The most wonderful thing about SMT machines is that they have the ability to operate by themselves. That is, they don't always require a human driver to operate them. SMT machines are able to be programmed to put the components in precisely where they're required. It saves companies considerable time and money by doing so automatically. They don't need to painstakingly worry about putting each small piece on the board just so by hand—rather, they set the machine up to do so. This leaves the staff free to give their attention to other essential things that make the whole production process fluid and faster.

Quicker Product Development

The efficiency level of SMT machines is very high. This makes it possible for manufacturers to develop new products very fast. They can prototype all different kinds of designs without taking too much time on what they are doing. For example, if a video games console manufacturer would like to produce buttons, haptic feedback units or whatever other product, they can implement it into SMT machines, and basically prototype idea concepts and designs. It allows them to produce new and innovative devices to buy. SMT machines also play a pivotal role in innovation for numerous organizations they allow for the generation of new concepts within the field of electronics

Produktion i høj kvalitet

Not only are smt screen printing machine quick, they are also very precise. That results in the parts being placed just where they need to be on the PCBs. That precision helps to make sure that the end product functions as it is supposed to. In one of the examples, if you install a piece in the opposite manner the whole machine will be non-functional or experience problems. Because SMT machines are extremely accurate, they make fewer errors, which makes the quality more superior when you are producing PCB. That is, when purchasing a gadget, you know that it was constructed effectively. Staying Ahead Of automatic chip mounter

Because more and more people desire to own electronic gadgets, manufacturers are obligated to make more PCBs to keep pace.

SMT machines assist them in doing that by producing more pcb monteringsudstyr in a short duration. It helps them keep pace with the boosted demand for electronics, without a compromise on quality. Without the automatic smd machine, the manufacturers would be at a loss when it comes to delivering enough product to the consumers on time, which would see many delays and cacophonous buyers. ConclusionIn summary, smt stencil cleaning machine change the game for PCB production.