Isang pangunahing gem ng paggawa sa modernong pamamahayag ng elektronika ay ang mga pick and place machine, na kumakarga ng maliit na komponente sa itaas ng circuit boards. Ang mga ito ay fundamental sa industriya, lalo na bilang ang elektronikong device ay nagiging mas maliit at mas kumplikado. Ngayon, tingnan natin ang ilang pinakamainit na pili para sa 2021 sa mga pick and place machine:

Yamaha YSM20R: ito siguradong hahawakan ang iyong pansin dahil sa impresibong bilis ng paglalagay na hanggang 90k komponente bawat oras (isang unang bilang sa industriya), na nagdadala ng Yamaha YMS sa taas na posisyon sa pagsasaayos. Hindi lamang makapaglalagay ng iba't ibang maliit na komponente mula sa 01005 microchips hanggang malalaking ICs at konektor ang makina na ito, kundi mayroon ding mataas na katumpakan na sistema ng pananaw na nagiging pinakamatalinong SMT pick and place machine.

Juki KE-3010VL: Ang modelong ito ay nag-aalok ng mabilis na paglalagay (hanggang 75,000 CPH) ngunit maaari rin itong magamit para sa mga komponente na may malaking sukat—mga komponente hanggang 33.5mm sa taas ay inilalagay nang walang problema sa makinang ito sa tulong ng kanyang sistema ng pagsentro sa laser, na nagbibigay talagang mabuting katatagan kahit para sa mga hindi patuloy o nababawasan na mga plapores. Nakakauwi ito ng mas maliit na espasyo sa sahig na mabuti para sa maliit na mga setup ng produksyon.

Sa pamamagitan ng kanyang kakayanang dalawang-dako at mabilis na pagganap na hanggang 20,000 CPH—kinikita ng Panasonic NPM-W2 ang unang premio sa fleksibilidad ng paglalagay. Ang mga pandamong may mataas na kaalaman sa makina ay nagpapahintulot sa lahat ng uri ng mga komponente, kabilang ang mga anyong baka at madelikadong mga device na macontrol. Mayroon din ang NPM-W2 ng kamera na may 12 megapixel na nagdedeliver ng kinakailangang katatagan sa pamamagitan ng kanyang sistema ng pananaw.

Sa paggawa ng mga elektroniko sa maliit na kalakhan, ang mga ekonomikong pick and place machine ay mahalaga dahil hindi praktikal ang malaking produksyon. Ang mga mas maliit na manufakturer ay hinahanap ang mga makamasa at madaling maintindihan na makina na may kaunting pamamahala samantalang pinapanatili ang kaparehong kalidad ng output. Ito ay mga magandang boto para sa pangangailangan ng maliit na kalakhan ng elektroniko:

NeoDen4 - Tinatakda para sa paggawa ng protopyo at maliit na batis na produksyon, ang NeoDen4 ay isang ekonomikong pilihan para sa mga SMEs upang pumili at ilagay ang mga komponente mula sa 0201 hanggang IC. May kasamang integradong kamerang sistema ang makina para sa tunay na pagluluwak at maaaring madaliang iprogram gamit ang mga file ng Gerber - ito ay inaasahang gagamitin ng isang tao.

Manncorp MC392: Nilikha ng Manncorp ang MC392 para sa maliit na kalakalan ng paggawa ng elektronika at ipinapadala ito sa isang kompakto, magkakamunting pakete. Ang sistemang pagsasanda at pagsusulok ng component na may awtomatikong bihasa ay nagpapatibay ng maayos na pagluluwas ng mga bahagi hanggang sa malalaking 50mm x 50mm! Maayos ang Windows-basehang software, at madaling gamitin ang interface.

Charmhigh CHM-T36VA: Kung may budget ka, may 0.025mm ng katumpakan ng pagluluwas ang Charmhigh CHM-T36VA. Kapaki-pakinabang na makapagluluwas ng mga 0402 component hanggang sa malalaking BGA chips at mayroon itong sistemang bihasa na may kamera na 5-megapixel para sa maayos na pagluluwas. Ang maliit na makinaryang ito ay isang mahusay na solusyon para sa mga gumagawa ng maliit na dami at madaling iprogram sa pamamagitan ng USB flash drive o PC software.

Isang sistema ng inspeksyon ng pananaw na kinabibilangan ng mga makina para sa pag-pick at place optimisa ang mga linya ng produksyon sa pamamagitan ng tiyak na pagluluwas ng mga bahagi habang dinadaanan din ang mga defektibong parte. Kinakailangan ang gamit ng mga makina para sa kontrol ng kalidad upang maiwanan ang isang pangkalahatang antas ng ekadensya at pababa ang posibilidad ng mga kahinaan. Nang walang masyadong dalaw, narito ang tatlong opsyon ng sistema ng inspeksyon ng pananaw para sa pick at place machines para sa'yo.

Fuji AIMEX III - Kayang magluwas ng hanggang 90,000 bahagi bawat oras (CPH), ang Fuji AIMEX III ay dating may isang mataas na resolusyong kamera na nagbibigay ng mahusay na alinment ng mga bahagi. Ang makina na ito ay may feature na sistemang inspeksyon sa pamamagitan ng x-ray sa real time, kasama ang inbuilt na spiral CT source upang tukuyin at korektahan ang mga defekto na maaaring nakita ng mga bahagi sa kanilang proseso ng paggawa, siguradong maituturing ang kalidad ng huling produkto.

Samsung SM482 - Ang Samsung SM482 ay maaaring ilagay hanggang 30,000 CPH at may high resolution vision system para sa tunay na paglalagay. Ang makina ay pinag-uunahan ng isang 2D at 3D inspection system na nagsusuri ng kalidad ng paglalagay ng mga komponente, real-time upang siguraduhing walang defektong boards ang inilalapat.

MYDATA MY200DX: Ang sistemang ito ay may rate ng paglalagay na 12,000 CPH (komponente bawat oras) at dating may isang onboard vision system para sa auto-checking ng mga komponente upang ilagay sila nang tumpak. Kasama rin sa setup ang isang 3D inspection system na nagsusuri ng kalidad ng mga parte patungo sa assembly, gumagawa ng mas konsistente ang mas magandang produksyon at mas mababa ang posibilidad ng mga error na mangyari.

Ang mga pick and place machine ay nagdadala ng dual-head capability sa larangan upang palakasin ang produktibidad sa paggawa ng elektroniko sa pamamagitan ng paggawa nila ng maramihang komponente sa isang pagkakataon. Ito'y katumbas ng mas mataas na produktibidad at mas taas na throughput sa production line. Kaya't handa na kayong makita ang ilang dual-headed pick and place machines:

Assembléon AX-501 — Ang Assembléon X4InOut ay may sistema ng dual-head upang makuha ang higit sa 48,000 komponenteng CPH ng isang beses. Kasama ang kanyang mataas na katumpakan vision system at auto component identification feature, ito ay siguradong minimizes ang oras ng setup at nagpapabuti sa produktibidad.

Fuji NXT III: Ang sistemang ito ay nagbibigay ng mabilis na pagluluwas hanggang 90,000 CPH at may dual-head set-up para sa mabilis na pagpipili at pagluluwas ng mga komponente. Kumakatawan ang makina ng mataas na resolusyong vision system na kaya ng mag-identify at maglugar ng mga komponente, kabilang ang maliit na 0201-sized microchips upang tiyakin ang katumpakan sa pagtatayo.

Panasonic NPM-W2DV: Ang sistemang ito na may double-sided dual-head ay maaaring ilagay ang mga parte sa dalawang lugar nang samahan. Pinag-equipo ito ng 12 M camera-based vision system para sa eksaktong pagluluwas at deteksyon ng defektuoso, habang nagdudulot sa proseso sa Freiberg at sa linya matapos ang pagtatayo.

Sa pamamagitan ng paglago ng teknolohiya ng 3D printing, ang pagsasama nito sa mga pick and place machine ay nangyayari na bilang isang magandang paraan upang idagdag ang mababang kosong prototyping para sa mga embedded systems. Maaari din ang 3D printing na palakasin ang mga manufacturer na gumawa ng espesyal na mga parte na kinakailangan para sa layunin ng pag-protoype na hindi madaling makuhang sa merkado. Narito ang ilang pick and place machines na may 3D printing:

Isang pick and place bulid na may mga parte na maaring iprint sa 3D: OpenPnP - ito ay isang open-source package upang mag-run ng isang pick&place machine, o gamitin bilang library para sa paggawa ng custom setups. Nakapag-install ito ng Vision system para sa wastong pagluluwas at kakayanang manangot ng mga komponente na laki ng 0201, kaya ito ay isang mabuting opsyon sa kategorya ng mga TYPE5 prototyping machines.

Dediprog SF100: Custom linear pick and place machine para sa pag-protoype, na ipinrinta sa 3D na may kumportable na paghahanda & user-friendly MCUI; Kasama ang built-in camera system at auto-focus, naglalagay ang SF100 ng mga komponente na lubos na wasto.

LitePlacer: isang 0402-laki na microchip at mas maliit pa ready pick-and-place machine na may open, gayunpaman maaring baguhin, frame upang magbigay ng kakayanang pagpersonalisasyon at madaling pagsasama-sama ng lego blocks (komponente). Ang makina na ito ay may mataas na resolusyon na kamera at laser positioning system na tumutulong sa tiyak na paglalagay ng mga komponente.

Upang sumuri, ang mga pick and place machine ay simpleng kinakailangang mga tool sa fini control na elektronikong assembly. Sa tuwing ang demand para sa mas maliit, mas kumplikadong elektroniko ay lumago at baguhin nang mabilis, hindi mapapabayaan ang pangangailangan para sa tiyak na assembly. 8 Pinakamahusay na Pick and Place Machines noong 2021. Maliban sa pinakamataas na pilihan para sa paggawa (maliit na skalang produksyon ng elektroniko), ang mga makina na may vision inspection systems, dual head capability machine & maliit na bersyon ng low cost pick & place na maaaring magbigay ng affordable solution sa antas ng prototipo.

Ang mga propesyonal na designer ay nagbibigay ng taas na kalidad ng makina ng pagpili at pagsasaalok na nakakamit ng mga kinakailangan ng mga customer. Ang modernong kagamitan ay magagamit upang suportahan ang disenyo ng spoiler. 3D printing CNC processing testing materials product simulations, ang pinakabagong teknolohiya ay nagbibigay ng malakas na pundasyon para sa pag-unlad ng spoiler.

Palaging pinipili namin ang mga partner sa machine ng pick place, kaya namin mong malaman na hindi posible ang tagumpay nang walang kanila. Sa loob ng global na Ecosystem, kumakBayan kami kasama ang pinakamahalagang mga partner upang magbigay ng mas mahusay na karanasan sa pagbebenta at mabuting suporta sa teknikal na aspeto.

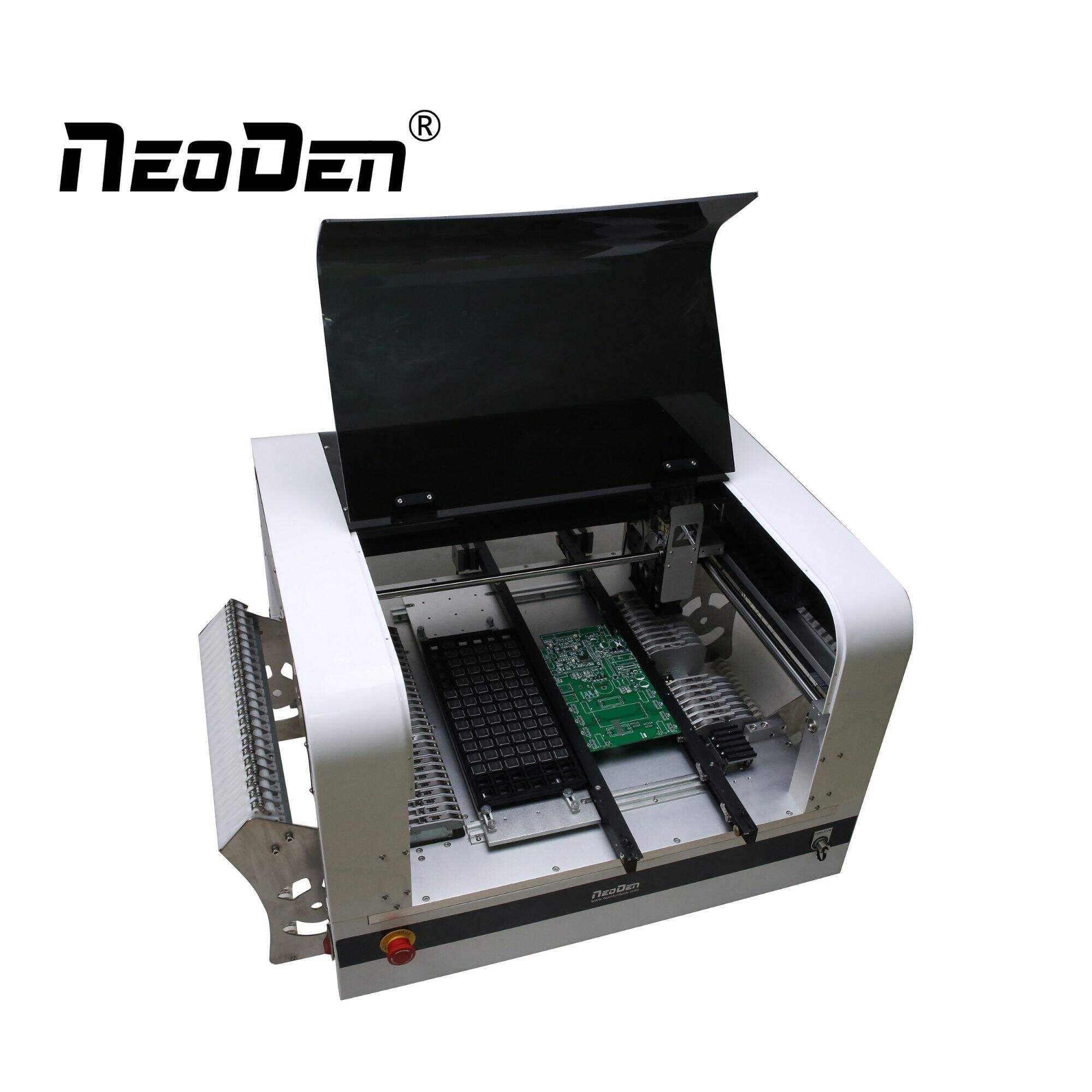

Ang napakagandang pagganap, mataas na precisions relihiyon ng NeoDen PNP pick place machine ay gumagawa ng perfekto para sa R&D, pang-eksperto na paggawa ng prototipo at maliit hanggang medium na produksyon. Sa nakaraang sampung taon, patuloy kaming nagpapaunlad ng ating teknolohiya, pagsisiyasat at pag-uunlad ng bagong produkto.

Si Zhejiang NeoDen Technology Co., Ltd. ay nagsisimula ng paggawa at pag-export ng maliit na pick place machines noong 2010. Gamit ang aming sariling anyos ng karanasan, marami naming pinili na pick place machine na may mataas na pagsasanay sa produksyon, nananatiling may malaking reputasyon sa mga customer sa buong mundo. Siguradong maaaring makapagbibigay kami ng mga product na sumasagot sa pangangailangan ng market at mga customer.

Copyright © Zhejiang NeoDen Technology Co., Ltd. All Rights Reserved - Patakaran sa Privasi