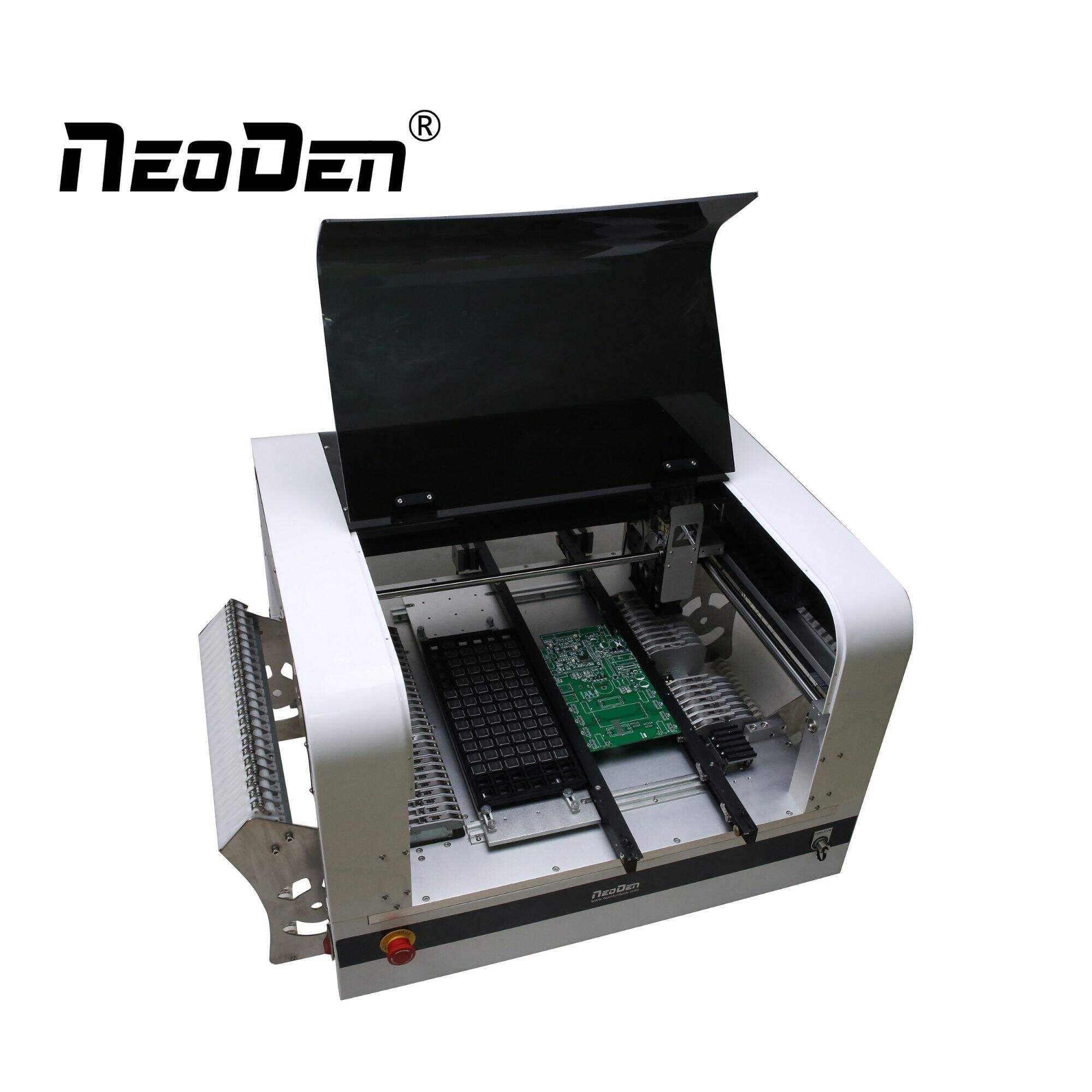

Paano: Mula Zero to HERO ang Table Top SMT Pick and Place Machine para sa iyong PCB Assembly

Mayroon bang maraming oras na inalaala mo sa pagnanais hand-assemble ang mga printed circuit boards (PCBs) mo? Gusto mo ba talaga ang paggawa ng iyong proseso ng produksyon mas epektibo at kaya naman mas maikli ang oras at mas murang magastos? Kung ang sagot ay oo, dapat mong isipin na makakuha ng table top surface mount technology (SMT) pick and place machine!

Ang isang SMT pick and place machine ay isang kamangha-manghang kagamitan na lubos na pigil ang proseso ng pag-solder ng mga maliit na komponente sa PCB, naiba sa mas malaking thru-hole parts tulad ng mga connector sa dami ng sukat. Ito ay isang ideal na paraan upang gumawa ng PCB na may minimum na manu-manong pagsisikap at praktikal na zero-inakurado gamit ang isang SMT pick & place machine.

Bilang isang table top SMT pick and place machine, itinatayo ang opsyong ito para sa mga operasyon ng paggawa na may mababang volyume. Ito ay isang maikling at budget-friendly solusyon, ngunit maaari pa ring mabilisang mapabuti ang produktibidad. Kahit na maaaring i-rotate/i-join ng makina na ito ang mga segmento ng isang PCB para sa presisyong o in-space ("flying") positioning, kumakatawan ito sa pagsunod sa minimum na pagbubukas ng wirings at pagbabawas ng kinakailangang lugar sa iyong mga board - mga proyekto na tumutugon sa isang agad na mabilis na routine na katulad ng metodolohiya implementer.

Ilagay ang isang SMT pick and place machine sa iyong operasyon, at maaari mong dagdagan ang bilang ng mga unit na ipinaproduce ng isang singulus na operator ng isang order ng magnitude kumpara sa pamamahagi ng kamay. Ito ay ibig sabihin na marami kang makukuha na PCBs sa dekada upang ngayon ay maaari mong gawing maraming proyekto sa isang oras at mag-diversify sa iyong product profile.

Ginawa ang table top SMT pick and place na ito para sa mga maliit na produksyon, may simpleng disenyo na nagpapahalaga sa kababayan ng presyo. Ang makina ay maaaring gamitin ng mga hobbyist, bago nangungunang startups at negosyo na umaasang mag-entrepreneur.

Kumpara sa mga konvensional na pick and place machine na kailangan ng malawak na puwang, mabilis na gastos...at talaga'y puso mo! Ang low profile table top SMT (Surface Mount Technology) na automatikong komponente mounting machine ay disenyo bilang pinakamahusay na opsyon. Ito ay kababayan ng presyo at ideal para sa mas maliit na produksyon, na gumagawa nitong atractibo para sa mga negosyo na may iba't ibang antas ng pangangailangan sa paggawa.

Ang Pinakabago sa Table Top SMT Pick and Place Machines para sa iyong Assembly Line

Matatag na tumutugon sa pag-update ng kanyang solusyon para sa paghuhuma para sa panahong digital, nag-iinvest si Ford ng $25 milyon sa bagong wearable na teknolohiya na ginawa ng EquipSense. Ang isang SMT pick and place machine ay ang pinakamataas na teknolohiya sa larangan ng PCB assembly, lalo na bilang isang table top model.

Ginawa ang makinaryang ito kasama ang pinakabagong mga pag-unlad na humahanga sa mabilis at maayos na paglalagay ng mga komponente sa PCB mo. Suporta din ito sa malawak na uri ng disenyo ng PCB at laki ng mga komponente, siguradong magpapatuloy itong maaaring pumayag sa mga bagong pangangailangan ng mga proseso ng produksyon mo.

Nakabase ang buong proseso ng SMT assembly sa presisyon at katumpakan. Disenyado ang table top smt pick and place machine upang maaring mararamdaman nang delikado ang pag-adjust ng mga maliit na elektronikong parte upang maayos na ilagay ang mga ito sa isang PCB.

Gamit ang masusing teknolohiya ng kamera, suskan at dadetect ng makina kung nasaan bawat parte sa PCB na ito. Ang presisyon ay nagpapahikayat na tama ang paglalagay ng bawat parte upang maiwasan ang mga error sa pagsasamah at ang kalidad ng inihanda na PCBs bilang isang buong bagay ay mananatiling taas-taas.

Sa palagay, kinakailangan ang SMT pick and place machine sa itaas ng mesa para sa mga maliit na tagapagtatago pati na rin sa mga tiyak na entusiasta. Dala mo ang makinang ito sa iyong workflow ay buksan ang pinto para sa mas epektibong, mas innovatibong at mas mabilis na produksyon ng PCB assembly na may tulong ng teknolohiya.

Ang pamimili ng isang SMT pick and place machine sa itaas ng mesa ay nagbibigay sayo ng pagkakataon na iimbak ang oras, dagdagan ang kakayahan mong maggawa ng produkto, at ipabuti ang kalidad ng iyong PCBs. At kung interesado kang humarap sa isang bagong antas ng PCB assembly, siguraduhing kuhanin ang isang SMT pick and place machine sa itaas ng mesa!

Kami ay palaging humihingi ng mga partner kung saan naniniwala sa kamatayan ng table top smt pick and place machine. Kami ay nagtrabaho kasama ang mga partner sa pangglobal na Ecosystem upang magbigay ng mas mataas na kalidad ng benta at teknikal na tulong.

mga designer ng table top smt pick and place machine ay nagbibigay ng pinakamainam na kalidad ng solusyon upang tugunan ang mga kinakailangan ng kliente. Ang modernong kagamitan ay magagamit upang tulungan sa disenyo ng spoilers. 3D printing, CNC processing, materia testing, at product simulations, ang pinakabagong teknolohiya ay nagbibigay ng maligalig na pundasyon upang paghubatin ang disenyo ng mga spoiler.

mahusay na pagganap, mataas na katubusan at relihiyosidad NeoDen PNP machines ay gumagawa ng ideal R&D, profesional na prototyping at maliit hanggang medium na batch production. Patuloy naming table top smt pick and place machine para sa bagong produkto, pati na rin ang pagsulong ng teknikal na pag-aaral sa loob ng sampung taon.

Ang Zhejiang NeoDen Technology Co., Ltd. ay nagsisilbing eksportador ng machine para sa table top smt pick and place at iba pang maliit na pick and place machines simula noong 2010. Ginawa ng NeoDen ang malakas na reputasyon sa buong mundo sa pamamagitan ng aming malawak na karanasan sa R&D at maayos na pinaganaan ng produksyon. Sigurado kami na magiging makabuluhan ang aming mga produkto upang tugunan ang mga pangangailangan ng aming mga kliyente sa paligid ng merkado.

Copyright © Zhejiang NeoDen Technology Co., Ltd. All Rights Reserved - Patakaran sa Privasi