| Place of Origin | China |

| Brand Name | NeoDen |

| Model Number | NeoDen IN12C |

| Certification | CE |

| Minimum Order Quantity | 1 pcs |

| Packaging Details | Wooden Package |

| Delivery Time | 10-25days |

| Payment Terms | 100% TT in Advance |

Description

1 Built-in welding fume filtration system, effective filtration of harmful gases, beautiful appearance and environmental protection, more in line with the use of high-end environment.

2. Hot air convection, excellent welding performance.

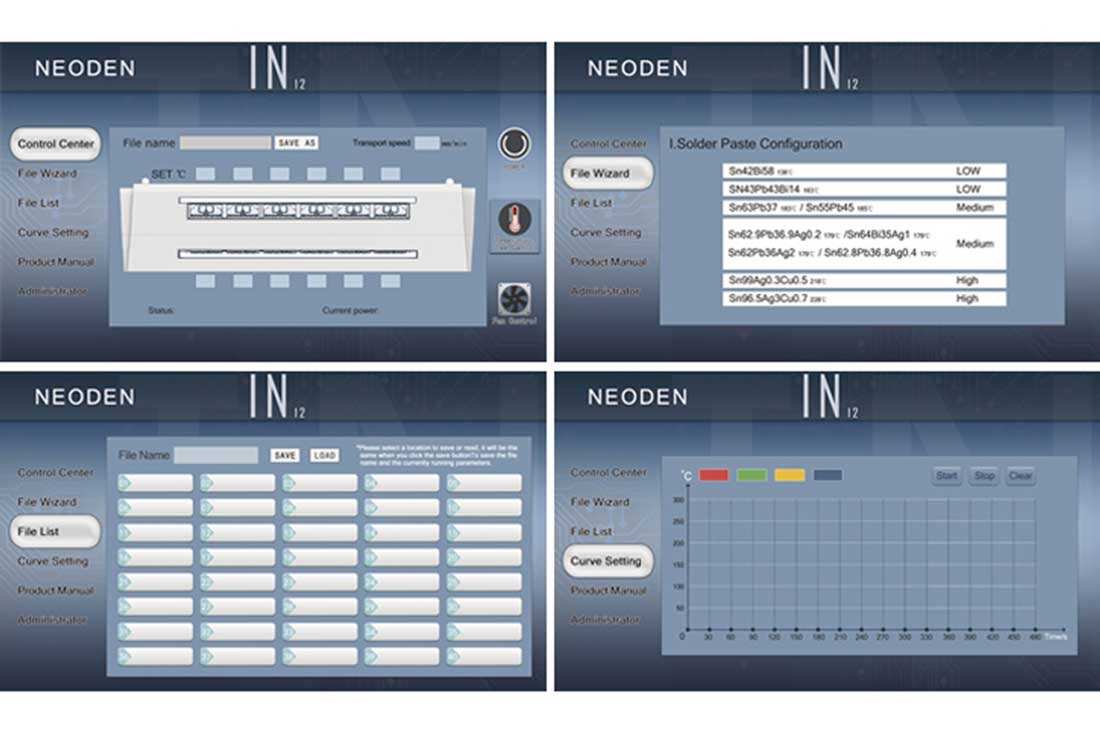

3. Intelligent, integrated with the PID control algorithm of the custom-developed intelligent control system, easy to use, powerful.

4. professional, unique 4-way board surface temperature monitoring system, so that the actual operation in a timely and comprehensive feedback data, even for complex electronic products can be effective.

5. Can store 40 working files.

6. Up to 4-way real-time display of PCB board surface welding temperature curve.

7. beautiful and has a red, yellow and green alarm function of the indicator design.

8. Independent circulating air design of the cooling area, completely isolated from the external environment on the internal temperature cavity.

9. through the special airflow simulation software test optimized welding fume filtration system, can achieve the filtration of harmful gases at the same time to ensure that the equipment shell to maintain room temperature, reduce heat loss and reduce power consumption.

10. All temperature zones and cold air zone wind speed adjustable, easily cope with a variety of welding needs.

11. Automatic limit after the top cover is opened, effectively ensure production safety.

Specifications

| Model | IN12C |

| Conveyor Type | Rail |

| Heating Zone Qty | Up 6/Down 6 |

| Heat Type | Nickel-chromium alloy wire and aluminum alloy heating |

| Cooling Zone Qty | Upper 4 fans |

| Rail Speed | 5-60cm/min |

| Maximum Height | Upper 30mm Down 15mm |

| Temperature Range | Room temperature ~300 celsius |

| Preheating Time | ~20-30mins |

| Maximum PCB Width | 300mm |

| Dimension | L2305*W612*H1230 |

| Peak power | ~4.8KW |

| Work power | ~2.2KW |

| Power Supply | 220V |

| Operation Direction | Left to right |

| Net Weight | 300kgs |

Details

|

|

|

|

|

|

Copyright © Zhejiang NeoDen Technology Co., Ltd. All Rights Reserved - Privacy Policy