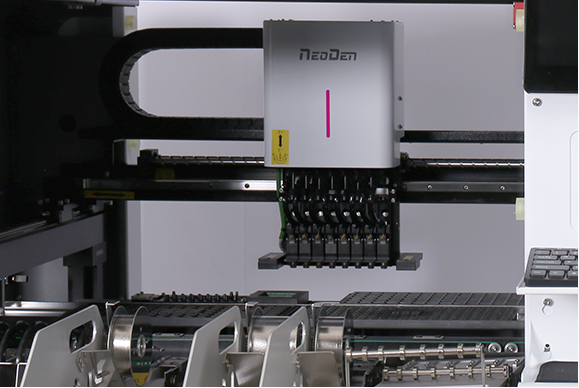

NeoDen N10P is a high-performance, easy-to-use and stable pick and place machine based on the original NeoDen10. The placement head is equipped with 8 independent nozzles, which can achieve high-speed placement with simultaneous pick up,as well as the maximum placement speed can reach 20,000CPH. It is equipped with a 39-hole fully automatic nozzle replacement device. Meanwhile, it can install a large feeder capacity of up to 80 tape feeders. It adopts imported servo drive with grinding screw configuration to greatly ensure the placement stability and repeated placement accuracy.

It is a cost-effective placement machine that you can rely on.

Features

Support PCB within size (L)1500mm*(W)450mm

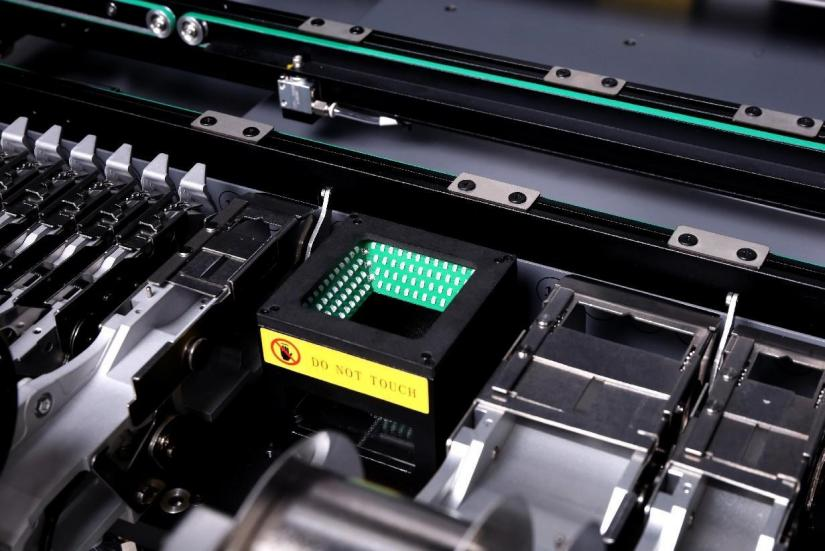

Automatic nozzle change function has been added to the system. 39 nozzle positions increase the speed and flexibility of integrated placement.

IC camera improves the size of IC photos and realizes automatic calibration with automatic nozzle change.

Automatic calibration of nozzle height

Increase the convenience of recycling material by adding a throw box.

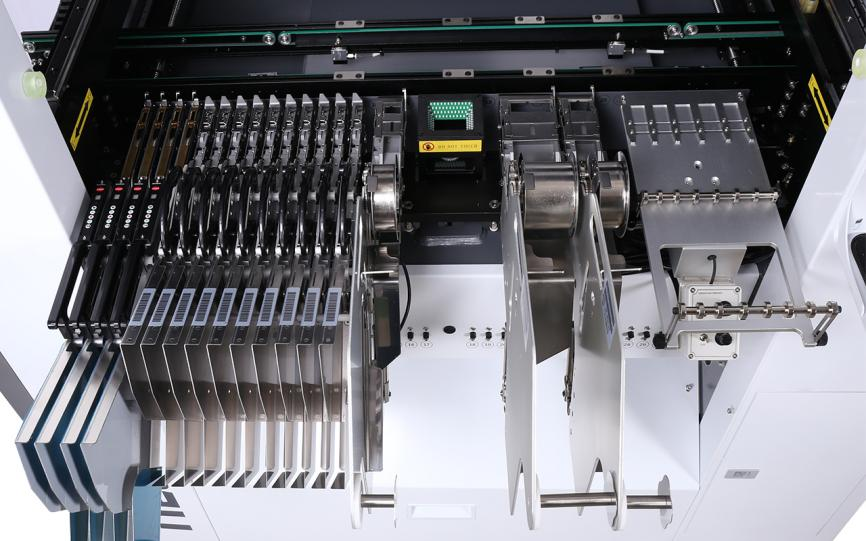

80 tape feeders to increase the number of simultaneous feeding capacity

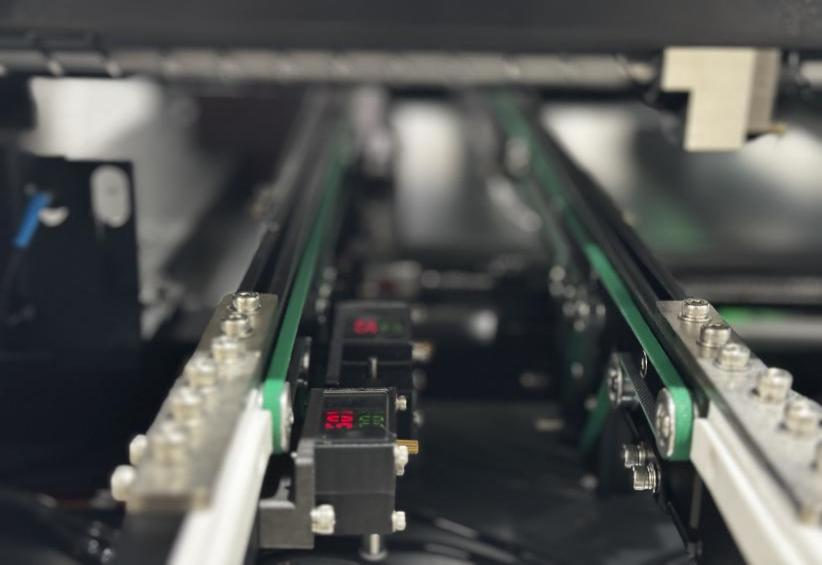

Measuring of nozzle air pressure to improve work stability and eliminate obstacles

Optimized software design to improve ease of use and stability

Specifications

| Number of Head | 8 | ||

| Speed | 20,000CPH(Max) | ||

| Position Accuracy | ±0.01mm | ||

| Camera Configuration | Dual Mark Camera+Front Flying Camera+IC Camera | ||

| Component Range | Flying Camera | 0201-22mmx22mm | |

| IC Camera | 0201-40mmx40mm | ||

| Max Height | 16mm | ||

| PCB Size | Min. | 50mmx50mm | |

| Max. | without IC tray | 450mm*1500mm | |

| with IC tray | 395mm*1500mm | ||

| PCB Thickness | 0.2mm-3.5mm | ||

| Feeder Capacity | Tape&Reel | 80pcs(33 front+47 rear) | |

| IC Tray | 1 | ||

| Automatic Nozzle Change | Yes | ||

| Support Pins to Hold PCB | Optional | ||

| Power | 600W, Single phase, 220V/110V, 50Hz/60Hz | ||

| Air Source | 0.6Mpa-0.8Mpa | ||

| Flow rate | 37L/min | ||

| XY Drive Type | WON Linear Guide/THK Grinding Screw C5-2040 | ||

| XY Drive Motor | Panasonic A6 750W Servo Motor | ||

| XY Motion Feedback Control | SPM/IBG Magnetic Linear Encoder | ||

| Weight | 1,000kgs | ||

| Dimension | 1289mmx1254mmx1386mm | ||

| Packing Size | 1320mmx1290mmx1456mm | ||

High Lights

8 heads with fully closed-loop control system support to pick up components simultaneously with maximum speed 20,000CPH.

Support 80 tape feeders, 20 stick feeders and 60 tray feeders, which achieve . Allows mixed use of electric and pneumatic feeders in the same feeder base.

Applicable to 1,500mm long board using an extension conveyor (optional).

Measuring of nozzle air pressure to improve work stability and eliminate obstacles.

Front and rear with 2 fourth generation high speed flying camera recognition systems, US ON sensors, 28mm industrial lens, for flying shots and high accuracy recognition.

Automatic nozzle change function with 39 nozzle slots tremendously increase placement speed and flexibility, reduce labor work.

Automatic calibration of nozzle height, manpower can be utilized efficiently.

Abnormal air pressure triggers placement pause to prevent potential damage and waste of materials.

Copyright © Zhejiang NeoDen Technology Co., Ltd. All Rights Reserved - Privacy Policy