| Place of Origin: | China |

| Brand Name: | NeoDen |

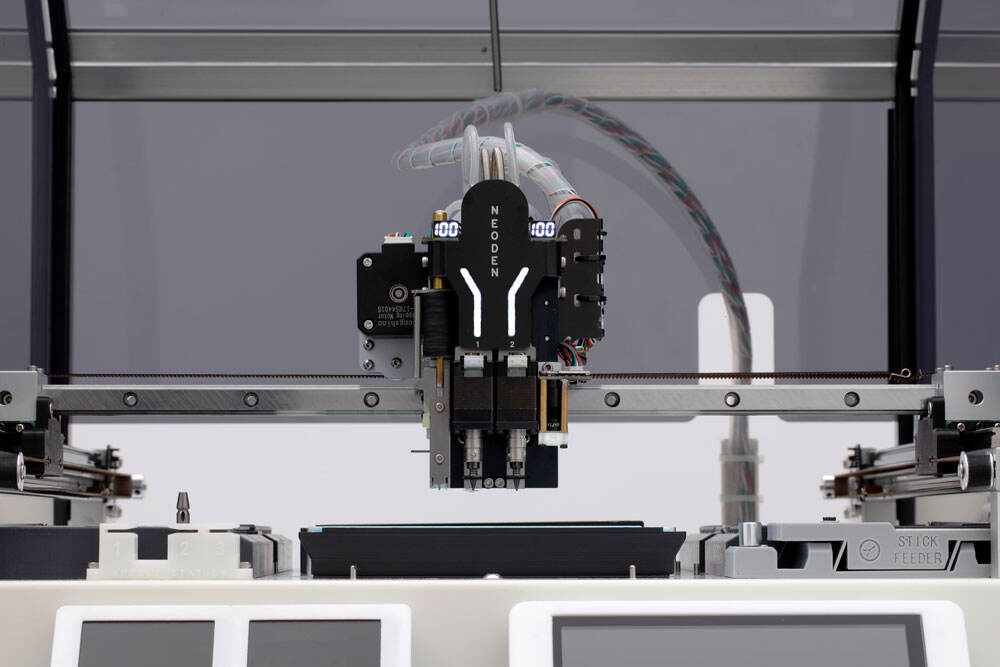

| Model Number: | NeoDen YY1 |

| Certification: | CE |

| Minimum Order Quantity: | 1 pcs |

| Packaging Details: | Wooden Package |

| Delivery Time: | 10-25days |

| Payment Terms: | 100% TT in Advance |

Description

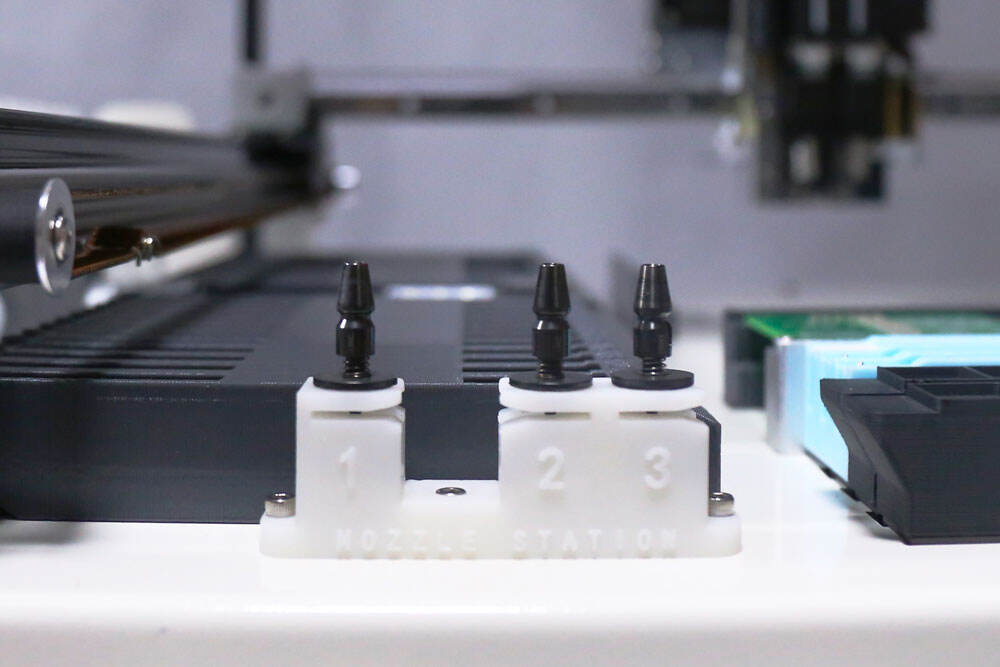

1. Automatic nozzle changer help realizing nozzles changed flexibly.

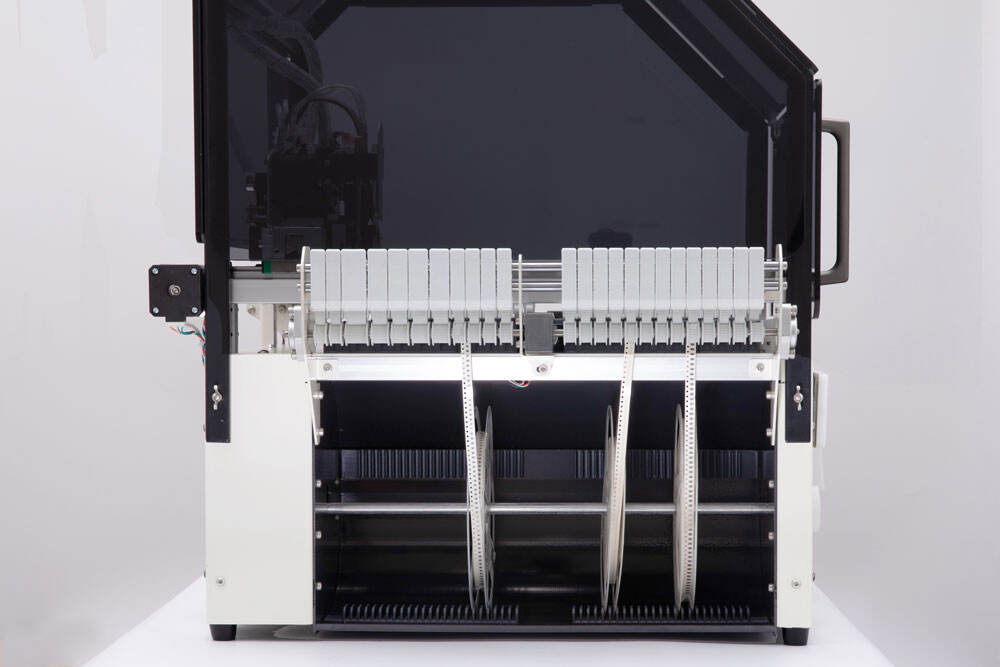

2. Supports bulk component feeder,strip feeder and IC tray feeder.

3. Independent high-definition & high-speed dual vision recognition systems,as well as dual cameras for real-time display the working status.

4. Newly designed software system & UI for visual programming and placement, which allows fast programming on the machine, friendly interface & easy operation.

5. Linear rail design for X, Y axis to ensure accuracy and stability,and reduce noise at the same time.

6. Patent-protected & new needle module is specially designed based on the linear rail with high reliability and durability.

7. Small size with powerful magazines and newly designed tape feeders to support large tape reels configuration flexibly,easy to install and replace tape reels conveniently,to ensure the most excellence solution among all of the entry level machines with lower budget but higher stability.

8. The newly-designed stick feeder with its compact shape, is perfectly compatible with the tape feeder system.

9. Comes with a high-definition capacitive touch screen, which can be adjusted up and down to meet the needs of different viewing angles and enhance the user experiences.

10. Fully transparent acrylic covers with magnetic mode for a high level of ease of disassembly.

11. Equipped with a vacuum detection function,can set standard vacuum detection values on placement head flexibly,all information can be displayed visually on the placement head.

Specifications

| Model Number | NeoDen YY1 | |

| Machine Style | Single Gantry With 2 Heads | |

| Alignment | Vision & Vacuum | |

| Placement Rate | Vision On | 3000CPH |

| Vision Off | 4000CPH | |

| Feeder Capacity | Tape Feeder: 52 (all 8mm) | |

| Stick Feeder: 4 | ||

| Flexible Feeder: 28 | ||

| Bulk Feeder: 19 | ||

| Nozzle Change Capacity | 3 Nozzles | |

| Component Range | Smallest Size | 0201 |

| Largest Size | 18x18mm | |

| Max Height | 12mm | |

| Rotation | ±180° | |

| Placement Accuracy | ±0.02mm | |

| X-Y Repeatability | ±0.02mm | |

| Z-axis Max Movement Range | 28mm | |

| PCB Applicable Dimension(mm) | Maximum 249 x 350(dual sides tape feeder) | |

| Maximum 315 x 350(single side tape feeder) | ||

| Electricity Supply | AC100V-240V | |

| Software System | Independent Development | |

| Control System | One-board Integration | |

| Drives System | Stepper Motor | |

| Positioning System | Fiducial Mark | |

| PCB Handling | Manual PCB Loading/Unloading | |

| Power | 50W | |

| External Dimensions(mm) | Machine Size | 643(L)x554(W)x601(H) |

Details

|

|

|

|

|

|

Copyright © Zhejiang NeoDen Technology Co., Ltd. All Rights Reserved - Privacy Policy