| Place of Origin | China |

| Brand Name | NeoDen |

| Model Number | NeoDen9 |

| Minimum Order Quantity | 1 pcs |

| Packaging Details | Wooden Package |

| Delivery Time | 10-25days |

| Payment Terms | 100% TT in Advance |

Technical Parameters

| Model Number | NeoDen9 | Repeat Position Accuracy | ±0.01mm |

| Number of Heads | 6 | Maximum Mounting Speed | 14,000CPH |

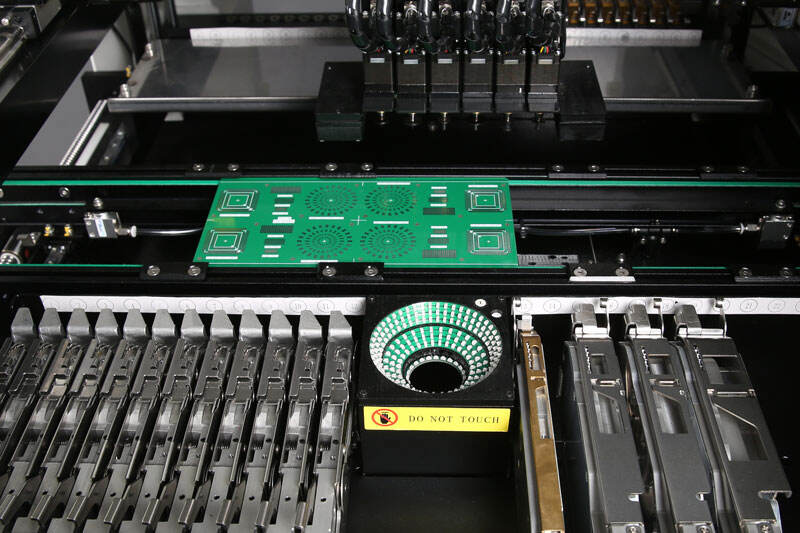

| Number of Tape reel Feeders | 53(Yamaha Electric/Pneumatic) | Average Mounting Speed | 9,000CPH |

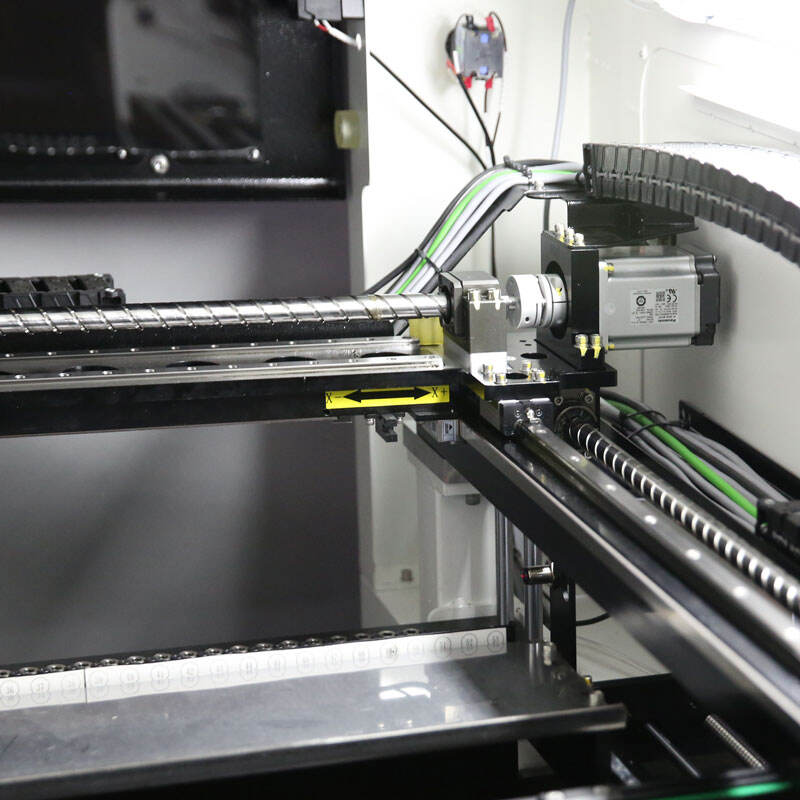

| Number of IC Tray | 20 | X-axis-Drive Type | WON Linear Guide / TBI Grinding screw C5 - 1632 |

| Placement Area | 460mm*300mm | Y-axis-Drive Type | WON Linear Guide / TBI Grinding screw C5 - 1632 |

| MAX Mounting Height | 16mm | Compressed Air | >0.6Mpa |

| PCB Fiducial Recognition | High Precision Mark Camera | Input Power | 220V/50HZ(110V/60HZ Alternative) |

| Component Recognition | High Resolution Flying Vision Camera System | Machine Weight | 500KG |

| XY Motion feedback control | Closed loop control system | Machine Dimension | L1220mm*W800mm*H1350mm |

| XY Drive motor | PanasonicA6 400W |

Details

|

|

|

|

|

Specification

1. The average mounting speed can be reached at 9000CPH.

The max mounting speed can be reached at 14000CPH.

2. NeoDen independent Linux software,to ensure the flexible and expedient upgrading. As well as easier operation and faster training.

2.1-click optimization function:

A. Mounting sequences.

B. Quick calibration of the picking position.

3. Equips Panosonic 400W servo motor,to ensure better torque and acceleration for achiving stable and durable placement.

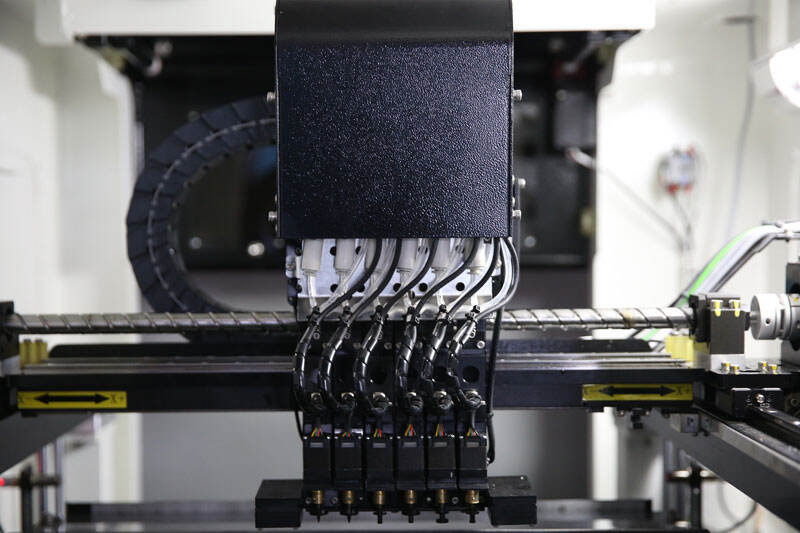

4. Independent control of 6 placement heads, each head can be up and down separately, easy to pick up, and the standard effective mounting height reach 16mm, meet the requirements of flexible SMT processing.

5-1. Supports both electric feeder and pneumatic feeder at max 53 slots tape reel feeders with machine width 800mm only, to ensure the high efficiency with flexible & worthiest space.

5-2. Equips with 2 mark cameras to ensure that all picking positions can be photographed.

5-3. Applicale for the maximum PCB width at 300mm, meets most of the PCB sizes.

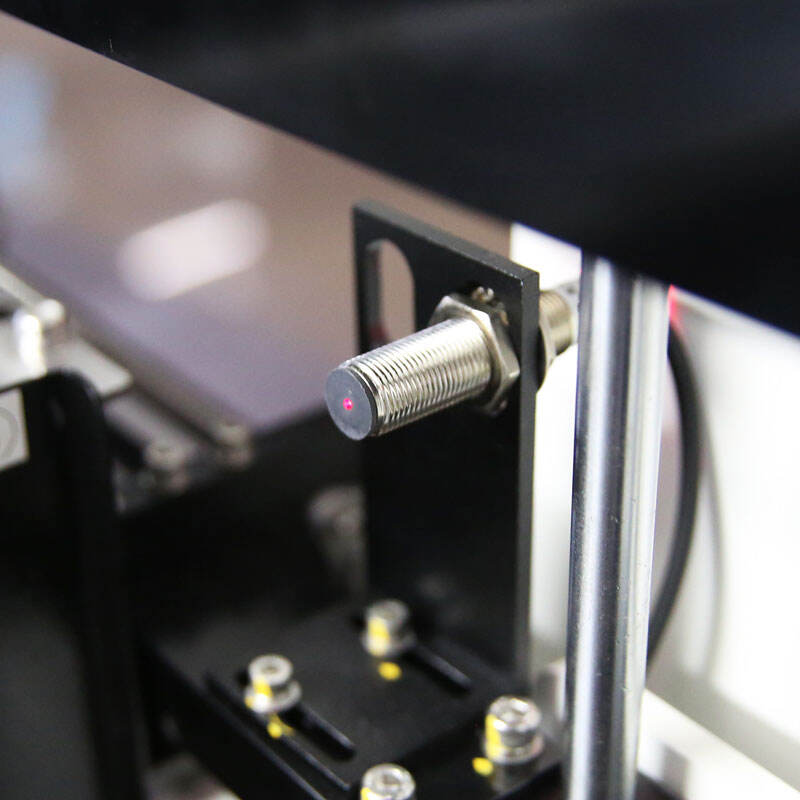

6. Equips with the magnetic scale technology what used commonly in the well-known brands, realizing true closed-loop control, long-term assurance of stable placement accuracy as initial & new conditions, easy to calibrate accuracy without suppliers' engineers.

Copyright © Zhejiang NeoDen Technology Co., Ltd. All Rights Reserved - Privacy Policy